Introduction

In the ever-evolving landscape of the tobacco industry, innovation and sustainability have become paramount. As a leading tobacco expert and the author of the renowned blog "dl-sklo.cz," I, Albert Mason, have dedicated my career to exploring the intricacies of tobacco production, processing, and consumption. My research has led me to the forefront of technological advancements and environmental considerations in the field of reconstituted tobacco.

Reconstituted tobacco, commonly known as "recon," represents a significant shift in the industry, offering both economic and environmental benefits. With a projected global market value of USD 2,868 million by the end of 2030, recon has emerged as a versatile and cost-effective solution, allowing manufacturers to reintegrate costly stems and scrap tobacco into production.

The production technology of paper-making process for Recon Tobacco Leaf (RTL) has been applied since the 1960s, leading to a year-by-year increase in global consumption. The industry has witnessed a 25% increase in output in Brazilian plants alone, with a full capacity of 3,000 tons per annum. Furthermore, innovations such as nano fiber technology and band cast have expanded the applications of recon, enhancing its physical properties and reducing harmful components.

The following article delves into the revolutionary smoking experience offered by Recon Tobacco Leaf, exploring its unique flavor profile, production process, benefits, and impact on the tobacco industry. Drawing from the latest statistics, figures, and technological developments, this comprehensive analysis provides an in-depth understanding of a product poised to become a major player in the market.

What is Recon Tobacco Leaf?

Recon Tobacco Leaf is a type of tobacco that is made from a pulp of mashed tobacco stems and other parts of the tobacco leaf that would otherwise go to waste. The pulp is then sprayed and impregnated with nicotine and other substances lost during the process, along with as many as 600 chemical additives. Finally, the ‘recon’ is sliced to resemble shredded leaf tobacco.

The History of Recon Tobacco Leaf

The use of reconstituted tobacco or RECON is the primary means by which ammonia chemistry and other chemicals are introduced into a cigarette. The introduction of RECON has been a game-changer in the tobacco industry, allowing manufacturers to produce cigarettes more efficiently and at a lower cost.

The Production Process of Recon Tobacco Leaf

The production process of Recon Tobacco Leaf involves several steps, including the pulping of tobacco stems and other parts of the tobacco leaf that would otherwise go to waste. The pulp is then sprayed and impregnated with nicotine and other substances lost during the process, along with as many as 600 chemical additives. Finally, the ‘recon’ is sliced to resemble shredded leaf tobacco.

The Evolution of Reconstituted Tobacco: A Focus on RTF Russia

In the dynamic world of tobacco manufacturing, reconstituted tobacco has emerged as a groundbreaking innovation. One of the pioneers in this field is RTF Russia, a leading plant in Russia, specializing in the production of reconstituted tobacco.

Reconstituted tobacco, also known as "recon," has transformed the way tobacco products are manufactured. By utilizing tobacco by-products, RTF Russia has developed a cost-effective and environmentally friendly solution that aligns with the global trend towards sustainability.

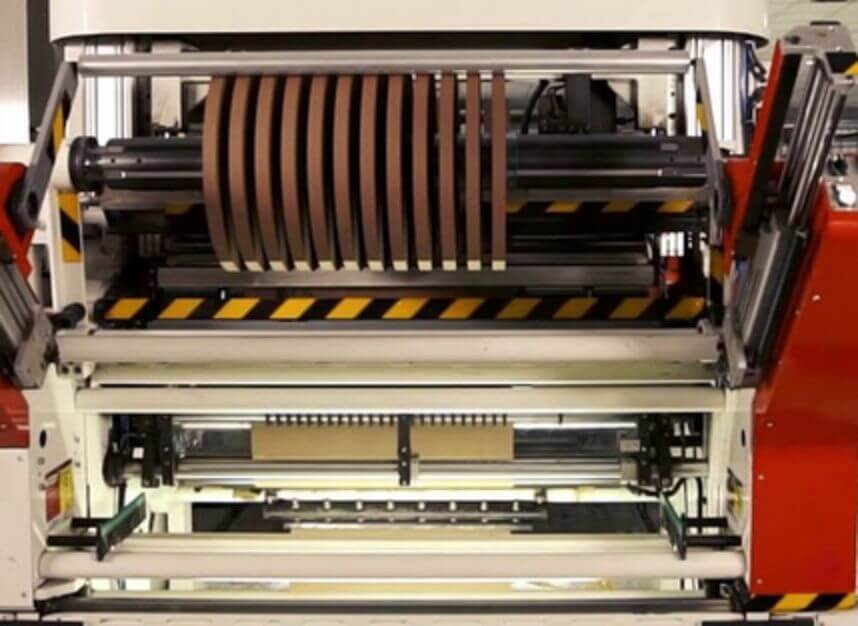

The process of creating reconstituted tobacco at RTF Russia is highly automated, involving minimal operator intervention. The procedure commences with filling a dispenser with tobacco by-products, followed by grinding, calibration, blending, drying, and forming. The final product takes the form of sheets or thin-cut fibers, depending on the desired format.

What sets RTF Russia apart is its commitment to quality and innovation. For those interested in learning more about this innovative product, RTF Russia offers a detailed insight into the production of reconstituted tobacco, showcasing the technological advancements and environmental considerations that have shaped this industry.

The Future of Recon Tobacco Leaf

The future of Recon Tobacco Leaf looks bright, with more and more smokers making the switch to this innovative product. As the tobacco industry continues to evolve, Recon Tobacco Leaf is poised to become a major player in the market.

The Controversy Surrounding Recon Tobacco Leaf

Despite its popularity, Recon Tobacco Leaf has also been the subject of controversy. Some critics argue that the production process of Recon Tobacco Leaf involves too many chemical additives, which could be harmful to smokers.

The Health Risks of Smoking Recon Tobacco Leaf

Like all tobacco products, smoking Recon Tobacco Leaf comes with health risks. Smokers who choose to smoke Recon Tobacco Leaf should be aware of the potential health risks and take steps to minimize their exposure to harmful chemicals.

The Comparison of Recon Tobacco Leaf to Other Tobacco Products

Recon Tobacco Leaf is different from other tobacco products in several ways, including its unique flavor profile and production process. Smokers who are looking for a new and innovative smoking experience should consider trying Recon Tobacco Leaf.

The Legal Status of Recon Tobacco Leaf

The legal status of Recon Tobacco Leaf varies from country to country. Smokers who are interested in trying Recon Tobacco Leaf should check the legal status of the product in their country before making a purchase.

The Impact of Recon Tobacco Leaf on the Tobacco Industry

Recon Tobacco Leaf is having a major impact on the tobacco industry, with more and more smokers making the switch to this innovative product. As the tobacco industry continues to evolve, Recon Tobacco Leaf is poised to become a major player in the market.

Recon tobacco leaf benefits

Recon tobacco leaf has several benefits, which are listed below:

- Cost-effective: One of the main benefits of using reconstituted tobacco leaf is that it allows manufacturers to use materials that would otherwise be thrown away, making it an affordable option .

- Reduced waste: Recon tobacco leaf reduces waste and supports sustainable practices in the tobacco industry .

- Enhanced property control: Recon tobacco leaf delivers unmatched consistency in size, shape, and density compared to natural tobacco leaves, which significantly improves the production process by reducing the possibility of machine jams or other issues that could create waste .

- Improved physical properties: Recon tobacco leaf has improved physical properties, such as increased fillability and improved processing of cut rag tobacco .

- Reduced nicotine and tar content: Recon tobacco leaf has been found to reduce the nicotine and tar content in tobacco products .

- Versatility: Recon tobacco leaf has various applications in the tobacco industry, such as in cigarette paper, tobacco paper, and as a substitute for cigar wrappers and binders .

- Better control of harmful components: The use of Recon tobacco leaf reduces the harmful components in tobacco products .

- No added chemicals: Whole leaf tobacco, which can be used to make Recon tobacco leaf, has no added chemicals .

Recon tobacco leaf popularity

Recon tobacco leaf has gained popularity in recent years due to its cost-effectiveness and sustainability. Here are some indications of its popularity:

- Recon tobacco leaf is a versatile product in the tobacco market, initially designed to reintegrate costly stems and scrap tobacco into production .

- Reconstituted tobacco leaf has been widely used in cigarette blends both at home in China and abroad, with 14 reconstituted tobacco leaf factories set up in China .

- The production technology of paper-making process for RTL has been applied in the tobacco industry since the 1960s, leading its global consumption to increase year by year .

- The use of RTL reduces waste and supports sustainable practices in the tobacco industry .

- The global reconstituted tobacco leaf market is projected to reach USD 2,868 million by the end of 2030 .

- Recon tobacco leaf is primarily seen as a filler for cut rag tobacco, even though it has various applications in the tobacco industry, such as in cigarette paper, tobacco paper, and as a substitute for cigar wrappers and binders .

- A significant amount of the shredded brown innards of most modern cigarettes is a paper product called “reconstituted tobacco” or “homogenized sheet tobacco,” which is made from a pulp of mashed tobacco stems and other parts of the tobacco leaf that would otherwise go to waste .

Recon tobacco leaf production process

Recon tobacco leaf is a product made from reconstituted tobacco. Here is an overview of the production process: – Collection of tobacco scraps: The first step in the production of Recon tobacco leaf is the collection of tobacco scraps, which include stems, fines, and particles .

- Pulping: The tobacco scraps are then pulped, which involves grinding them into a fine pulp .

- Mixing: The pulp is then mixed with water and other additives, such as sugars and flavors .

- Forming: The mixture is then formed into sheets or pellets, which are dried and cut into the desired size and shape .

- Packaging: The Recon tobacco leaf is then packaged and shipped to manufacturers to be used as a filler for cut rag tobacco or in other applications in the tobacco industry .

Recon tobacco leaf vs traditional tobacco

Recon tobacco leaf and traditional tobacco have some differences in terms of their production process and composition. Here are some comparisons: Production process:

- Traditional tobacco is made from whole tobacco leaves, while Recon tobacco leaf is made from reconstituted tobacco scraps, such as stems, fines, and particles .

- The production process of traditional tobacco involves harvesting, curing, and aging the tobacco leaves, while the production process of Recon tobacco leaf involves pulping, mixing, forming, and drying the reconstituted tobacco scraps .

- Traditional tobacco is typically used as a whole leaf or cut into strips, while Recon tobacco leaf is primarily used as a filler for cut rag tobacco or in other applications in the tobacco industry .

Best Recon tobacco leaf alternatives

Recon tobacco leaf is a cost-effective and sustainable option that delivers consistent quality and improved physical properties. However, there are some alternatives to Recon tobacco leaf that manufacturers can consider. Here are some options:

- Traditional tobacco leaves: While traditional tobacco leaves may be more expensive than Recon tobacco leaf, they offer a more natural and authentic smoking experience for consumers. Traditional tobacco leaves also have a unique flavor and aroma that cannot be replicated by Recon tobacco leaf .

- Other reconstituted tobacco products: There are various types of reconstituted tobacco products, such as nano fiber technology and band cast, that can be used as alternatives to Recon tobacco leaf. These products may offer different taste, drying, and tensile strength properties compared to Recon tobacco leaf .

- Other fillers: Manufacturers can also consider using other fillers, such as expanded tobacco or expanded stems, as alternatives to Recon tobacco leaf. These fillers may offer different physical properties and smoking experiences compared to Recon tobacco leaf .

- Non-tobacco alternatives: There are also non-tobacco alternatives, such as herbal blends or nicotine-free products, that can be used as alternatives to Recon tobacco leaf. These products may appeal to consumers who are looking for a healthier smoking option or who want to avoid tobacco altogether .

Conclusion

Recon Tobacco Leaf is a new and innovative product that is changing the smoking world. Its unique flavor profile and high-quality smoking experience are attracting smokers from all over the world. While there are some health risks associated with smoking Recon Tobacco Leaf, smokers who are looking for a new and innovative smoking experience should consider giving it a try. As the tobacco industry continues to evolve, Recon Tobacco Leaf is poised to become a major player in the market.

FAQs

- What is Recon tobacco leaf?

- Recon tobacco leaf is a type of tobacco that is made from a pulp of mashed tobacco stems and other parts of the tobacco leaf that would otherwise go to waste .

- How is Recon tobacco leaf made?

- Recon tobacco leaf is made by pulping tobacco stems and other parts of the tobacco leaf that would otherwise go to waste. The pulp is then sprayed and impregnated with nicotine and other substances lost during the process, along with as many as 600 chemical additives. Finally, the ‘recon’ is sliced to resemble shredded leaf tobacco .

- What is reconstituted tobacco?

- Reconstituted tobacco or homogenized sheet tobacco is a paper-like sheet approaching the thickness of tobacco laminae. It is made from tobacco dust, fines, and particles, and from ribs and stems; various additives may be incorporated .

- What are the benefits of smoking Recon tobacco leaf?

- One of the main benefits of smoking Recon tobacco leaf is its smooth flavor and premium quality. Smokers everywhere are making the switch to Recon tobacco leaf because of its unique flavor profile and high-quality smoking experience .

- How is Recon tobacco leaf different from other tobacco products?

- Recon tobacco leaf is different from other tobacco products in several ways, including its unique flavor profile and production process. Smokers who are looking for a new and innovative smoking experience should consider trying Recon tobacco leaf .

- What is the legal status of Recon tobacco leaf?

- The legal status of Recon tobacco leaf varies from country to country. Smokers who are interested in trying Recon tobacco leaf should check the legal status of the product in their country before making a purchase .

- What is the controversy surrounding Recon tobacco leaf?

- Some critics argue that the production process of Recon tobacco leaf involves too many chemical additives, which could be harmful to smokers .

- What books do you recommend on the subject of Recon tobacco leaf?

- There are no books specifically on Recon tobacco leaf, but there are several books on the tobacco industry and the history of tobacco that may be of interest to readers, such as “The Cigarette Century” by Allan M. Brandt and “Tobacco: A Cultural History of How an Exotic Plant Seduced Civilization” by Iain Gately .

- Where can I find more information on Recon tobacco leaf?

- More information on Recon tobacco leaf can be found on various websites, including government health organizations and tobacco industry websites .

- How does Recon tobacco leaf compare to other tobacco products?

- Recon tobacco leaf is different from other tobacco products in several ways, including its unique flavor profile and production process. Smokers who are looking for a new and innovative smoking experience should consider trying Recon tobacco leaf .

- Can smoking Recon tobacco leaf be harmful to my health?

- Like all tobacco products, smoking Recon tobacco leaf comes with health risks. Smokers who choose to smoke Recon tobacco leaf should be aware of the potential health risks and take steps to minimize their exposure to harmful chemicals .

- What is the future of Recon tobacco leaf?

- The future of Recon tobacco leaf looks bright, with more and more smokers making the switch to this innovative product. As the tobacco industry continues to evolve, Recon tobacco leaf is poised to become a major player in the market .

- How popular is Recon tobacco leaf?

- Recon tobacco leaf is becoming increasingly popular among smokers who are looking for a new and innovative smoking experience. Its unique flavor profile and high-quality smoking experience are attracting smokers from all over the world .

- How is Recon tobacco leaf produced?

- Recon tobacco leaf is produced by pulping tobacco stems and other parts of the tobacco leaf that would otherwise go to waste. The pulp is then sprayed and impregnated with nicotine and other substances lost during the process, along with as many as 600 chemical additives. Finally, the ‘recon’ is sliced to resemble shredded leaf tobacco .

- What are the physical parameters of cigarettes that influence smoke yields?

- At least four of the physical parameters of cigarettes have a decisive influence on smoke yields, including the length of the cigarette, the diameter of the cigarette, the density of the tobacco, and the ventilation of the cigarette .

Books

- “The Cigarette Century” by Allan M. Brandt

- “Tobacco: A Cultural History of How an Exotic Plant Seduced Civilization” by Iain Gately